We also provide the option of refurbishing your existing mesh sling furniture. The major benefit of our refurbishing service is that it provides substantial savings over the cost of purchasing new furniture. Many times the existing furniture frames are in good condition and do not need to be replaced with new furniture, so replacing the sling / fabric material is a great money saving option.

This process begins with a factory representative picking up your furniture, leaving loaner furniture if required and returning to our factory located in Milton, Florida.

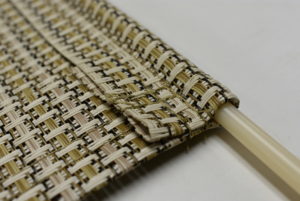

Measurements are calculated and the new material (of your choosing) is rolled off of the "bolt" of fabric and cut to the correct size using an electric, Falcon IV end cutter to assure that each sling is cut to our exact specifications. Most of the replacement outdoor fabric that we use is manufactured by The Twitchell Corporation in Dothan, AL (www.twitchellcorp.com) or Phifer Corporation in Tuscaloosa, AL (www.phifer.com).

Our new sewing station allows us to sew each sling in house using a brand new commercial, double needle sewing machine.

During the sewing procedure new "spline" of the proper diameter is installed into the sling as it goes into the double stitch sewing machine, so that the sling fits into the frame track of the lounge or chair correctly.

Meanwhile the frames are stripped of all the old mesh-fabric-sling material and then each frame is pressure-washed. Then the frames are checked for any broken welds, which are TIG-welded and touched-up as required. Any broken back adjusters and frame braces are repaired or replaced. All back-bottom hinge pins are replaced with new stainless steel hardware and all nylon glides are replaced with new inserts when possible.

Finally the new fabric mesh slings are installed and your furniture is prepared for return delivery.